Optimizing Ductwork for Comfort and Energy Savings

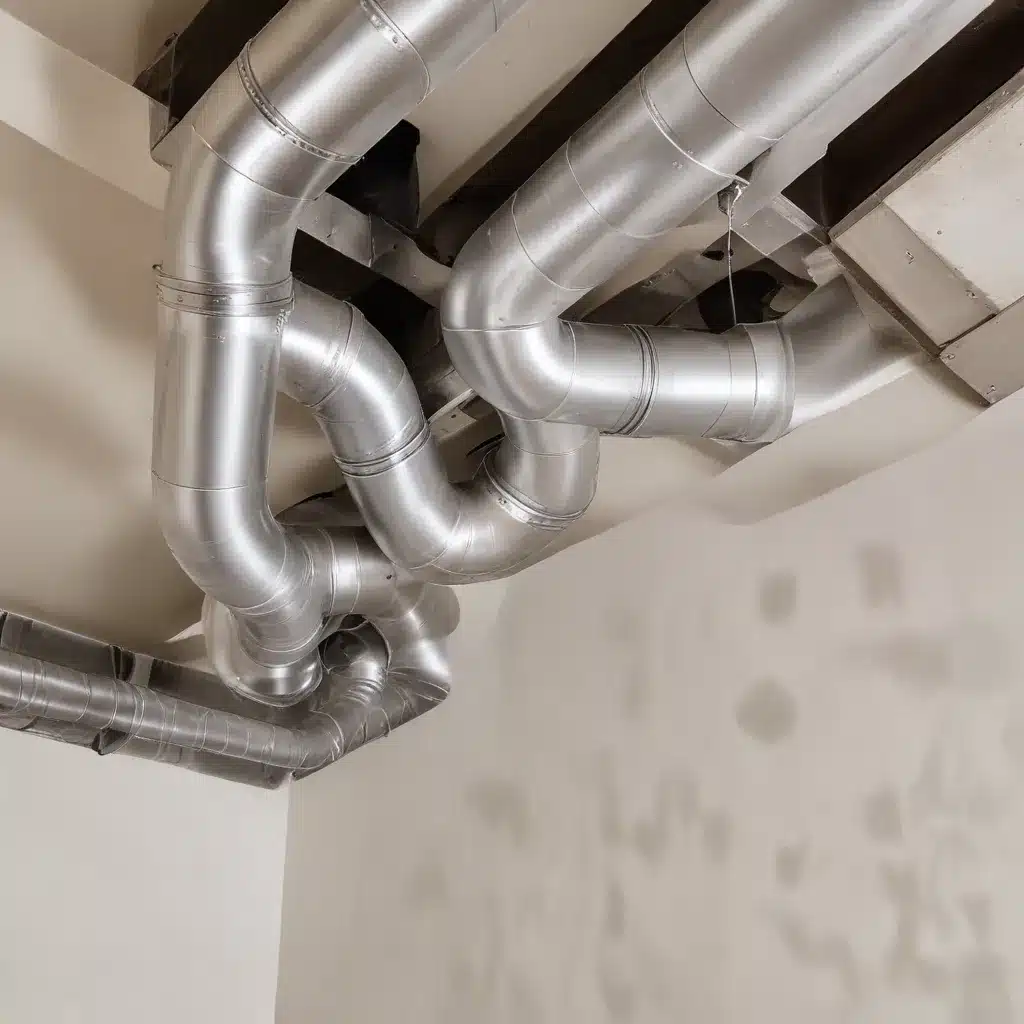

As an experienced air conditioning specialist, I’ve seen firsthand the critical role ductwork plays in the overall performance and efficiency of HVAC systems. The intricate network of ducts that snake through our homes and buildings is often the unsung hero, responsible for delivering the conditioned air that keeps us comfortable year-round. But ductwork design is no simple task – it requires a deep understanding of airflow dynamics, thermal dynamics, and building construction to create a system that operates at its peak efficiency.

One of the primary advantages of well-designed ductwork is the ability to ensure even and consistent air distribution throughout a home or commercial space. Imagine stepping from one room to another and feeling a noticeable difference in temperature – that’s often a telltale sign of an imbalanced duct system. By carefully sizing, routing, and insulating the ducts, we can achieve a seamless flow of air, maintaining the desired temperature and comfort levels in every corner of the building.

But the benefits of optimized ductwork go beyond just comfort. Efficiency is another crucial factor that drives our work at https://www.hamiltonaircon.co.uk/. Properly designed ducts minimize airflow resistance, reducing the strain on the HVAC equipment and resulting in lower energy consumption. This translates to tangible cost savings for homeowners and businesses, not to mention the environmental benefits of reduced carbon footprint.

Understanding the Anatomy of Ductwork

To truly master the art of ductwork design, it’s essential to have a solid understanding of the various components that make up a duct system. At the most basic level, ductwork consists of the primary conduits that carry the heated or cooled air, as well as the various fittings and accessories that assist in directing, controlling, and distributing that air.

One of the fundamental choices in duct design is the shape: round, rectangular, or oval. Each option has its own advantages and considerations. Round ducts, for instance, are renowned for their efficiency in airflow, as the smooth interior surfaces minimize turbulence and pressure losses. Rectangular ducts, on the other hand, offer greater flexibility in terms of routing and installation, particularly in tight spaces. Oval ducts provide a happy medium, combining some of the benefits of both round and rectangular designs.

Beyond the basic shape, the gauge or thickness of the duct material is another crucial factor. Thicker, more durable sheets are typically used for higher-pressure systems or in areas where the ducts may be subjected to physical stress. Proper insulation is also a must, as it helps prevent heat transfer and condensation issues – both of which can significantly impact the system’s overall efficiency.

Duct fittings, such as elbows, transitions, and dampers, play a vital role in the air distribution process. These components allow for smooth directional changes, adjustments in duct size, and fine-tuning of airflow, ensuring that the conditioned air reaches its intended destinations without unnecessary turbulence or pressure drops.

Factors Influencing Ductwork Design

Designing an efficient duct system is a complex process that requires consideration of a wide range of factors. Let’s delve into some of the key elements that shape the ductwork in both residential and commercial applications.

Building Characteristics

The physical attributes of the building itself have a significant impact on ductwork design. Factors like the size, layout, and construction materials all come into play. A sprawling, multi-story home will require a fundamentally different duct system than a compact, single-level apartment. Understanding the building’s thermal envelope – its insulation, windows, and air leakage characteristics – is crucial for accurately calculating heating and cooling loads, which in turn inform the ductwork design.

Climate Conditions

The local climate is another essential consideration. Ductwork in a temperate region with mild seasons will have different requirements compared to a system designed for an area with extreme temperature swings or high humidity levels. Accounting for these environmental factors ensures that the ductwork can effectively distribute the conditioned air, maintaining comfort and energy efficiency regardless of the outdoor conditions.

Occupant Needs

At the end of the day, the primary purpose of any HVAC system is to provide a comfortable indoor environment for the building’s occupants. Their specific needs and preferences must be factored into the ductwork design. Things like the number of occupants, their activity levels, and their thermal comfort requirements all play a role in determining the appropriate airflow, temperature, and zoning strategies.

Energy Efficiency and Sustainability

In today’s world, energy efficiency and environmental sustainability are paramount concerns. Ductwork design must prioritize minimizing energy consumption and reducing the carbon footprint of the HVAC system. This can be achieved through strategies like optimizing duct sizing, using high-performance insulation, and incorporating advanced control systems to fine-tune the air distribution.

Designing Efficient Ductwork

Crafting an efficient duct system is a multi-faceted process that requires a methodical approach and a keen understanding of HVAC principles. Let’s explore the key steps involved in designing ductwork that delivers optimal performance and energy savings.

Load Calculations

The first step in the ductwork design process is to accurately calculate the heating and cooling loads for the building. This involves a detailed analysis of factors such as the building’s size, orientation, thermal envelope, and occupancy patterns. By precisely determining the amount of conditioned air required to maintain comfort, we can then size the ductwork accordingly, ensuring that the system has the capacity to meet the demands without over-or under-delivering.

System Selection

With the load calculations in hand, the next step is to select the appropriate HVAC system type and components. This decision is influenced by considerations like the building’s size, occupancy, and specific requirements. Common system types include split systems, packaged units, and central air systems, each with their own unique ductwork design considerations.

Duct Sizing and Layout

One of the most critical aspects of ductwork design is the precise sizing and routing of the ducts. This involves calculating the necessary airflow rates for each zone or room, and then designing the duct network to deliver the conditioned air efficiently. Factors like duct length, bends, and branch takeoffs must be carefully balanced to minimize pressure drops and ensure even air distribution.

Material and Insulation Selection

The choice of duct material and insulation is paramount for both performance and energy efficiency. Galvanized steel, aluminum, and various types of ductboard are common options, each with their own advantages and considerations. Proper insulation not only helps maintain the temperature of the conditioned air but also prevents energy losses and condensation issues.

Airflow Balancing

Once the ductwork is installed, the system must be carefully balanced to ensure that the right amount of air is delivered to each zone. This involves adjusting dampers, vents, and other components to fine-tune the airflow, optimizing comfort and energy efficiency.

Residential Ductwork Design Considerations

While the general principles of ductwork design apply to both residential and commercial buildings, there are some unique considerations when it comes to home HVAC systems. Let’s explore a few of the key factors that come into play when designing ductwork for a residential setting.

Zoning and Individualized Control

In larger homes or homes with varying occupancy patterns, zoning systems can be implemented to provide personalized temperature control for different areas or rooms. This might involve the use of multi-stage equipment or the incorporation of dampers and thermostats to regulate airflow to specific zones.

Ventilation and Indoor Air Quality

Proper ventilation is crucial in residential ductwork design to maintain healthy indoor air quality. Strategies such as whole-house ventilation systems, energy recovery ventilators (ERVs), and heat recovery ventilators (HRVs) can be employed to introduce fresh outdoor air while minimizing energy losses.

Noise Considerations

In residential settings, noise from HVAC equipment and ductwork can be a significant concern, as occupants are in close proximity to the systems. Careful equipment selection, vibration isolation, and duct routing and design can all help mitigate noise levels and ensure a comfortable living environment.

Commercial Ductwork Design Challenges

When it comes to commercial buildings, the ductwork design process faces its own unique set of challenges. Let’s explore some of the key considerations that come into play in these larger, more complex HVAC systems.

Zoning and Load Diversity

Commercial buildings often have diverse occupancy patterns and varying heating and cooling requirements across different zones or areas. Ductwork design must account for this load diversity, ensuring that the system can efficiently distribute conditioned air where it’s needed most, without over-or under-serving any particular zone.

Ventilation and Indoor Air Quality

Maintaining proper indoor air quality is crucial in commercial buildings, where occupants spend a significant portion of their time. The ductwork design must account for ventilation requirements based on occupancy levels and potential sources of indoor air pollutants.

Energy Efficiency and Sustainability

In the commercial realm, energy efficiency and sustainability are paramount concerns. Ductwork design strategies, such as the use of energy recovery systems and demand-controlled ventilation, can play a vital role in reducing the overall energy consumption and carbon footprint of the HVAC system.

Integration with Building Automation Systems

Commercial HVAC systems often incorporate sophisticated building automation and control systems (BAS) to optimize performance, monitor energy consumption, and enable remote monitoring and control. Integrating the ductwork design with these advanced control systems is crucial for achieving the desired level of efficiency and responsiveness.

Embracing the Future of Ductwork Design

As the HVAC industry continues to evolve, the future of ductwork design is poised to embrace a range of exciting technological advancements and innovative approaches. Let’s explore some of the emerging trends that are shaping the way we design and optimize air distribution systems.

Smart HVAC Integration

The integration of HVAC systems with Internet of Things (IoT) technologies and smart building platforms is revolutionizing ductwork design. Smart sensors, cloud-based analytics, and machine learning algorithms can be leveraged to monitor duct performance, detect potential issues, and optimize airflow in real-time.

Renewable Energy Integration

As the demand for sustainable solutions grows, the incorporation of renewable energy sources, such as solar photovoltaic (PV) systems or geothermal heat pumps, into ductwork design is becoming more prevalent. These technologies can not only reduce the overall energy consumption but also contribute to a lower carbon footprint for the building.

Modular and Prefabricated Ductwork

The adoption of modular and prefabricated ductwork systems is gaining traction in the industry. These solutions, designed and assembled in controlled factory environments, offer the potential for faster installation, improved quality control, and reduced on-site labor requirements.

Advancements in Refrigerants and Cooling Technologies

The HVAC industry is continuously exploring alternative refrigerants and cooling technologies that have lower environmental impact and improved energy efficiency. From the use of low global warming potential (GWP) refrigerants to the emergence of innovative cooling systems like magnetic cooling and advanced absorption cooling, the future of ductwork design is poised to accommodate these transformative advancements.

BIM and Digital Twins

The integration of Building Information Modeling (BIM) and digital twin technologies is revolutionizing the ductwork design process. BIM enables the creation of detailed 3D models that facilitate coordination, visualization, and clash detection, while digital twins enable virtual simulations and predictive maintenance strategies.

As an experienced air conditioning specialist, I’m excited to see how these technological advancements and innovative approaches will continue to shape the future of ductwork design. By embracing these emerging trends and continuously improving our knowledge and skills, we can create HVAC systems that not only provide optimal comfort and efficiency but also contribute to a more sustainable built environment.